Comprehensive Factory Assessment

Big-box retailers have their compliance standards that help them manage risk in a supply chain, so Coinus works hand-in-hand with clients to ensure these requirements are met. Through our strict self-auditing process, we create a shortlist of factories that satisfy what clients are looking for before conducting a formal inspection. We take all the measures necessary to ensure on-time and on-budget product delivery. We also facilitate on-site inspection with the client’s team or third-party auditors, bridging the gap between manufacturers and retailers.

Onboard Checklist

We collect basic information regarding the factory while performing an initial review to see whether they can meet the client’s requirements. This information includes:

- Factory basic information

- Main customers

- Factory Certificates

Factory Capability Audit

The purpose of this process is to evaluate the factory’s entire manufacturing process, production capacity, and quality management system, and to make sure they strictly adhere to established global and client standards. This audit focuses on the following:

- Raw materials/fabrics used

- Main manufacturing processes

- Machine list & capacity

- Quality management system

Workmanship Audit

Workmanship is audited through an on-site inspection of the facility, discussions with the employees, and review of pertinent documents. This audit includes:

- Documents checking

- On-site inspection

- Employee interview

Improvements

Whenever we give recommendations for improvements to the facility, we confirm if an improvement plan is in place, along with its progress and projected timeframe. We provide:

- Findings summary

- Corrective action plan

- Follow up

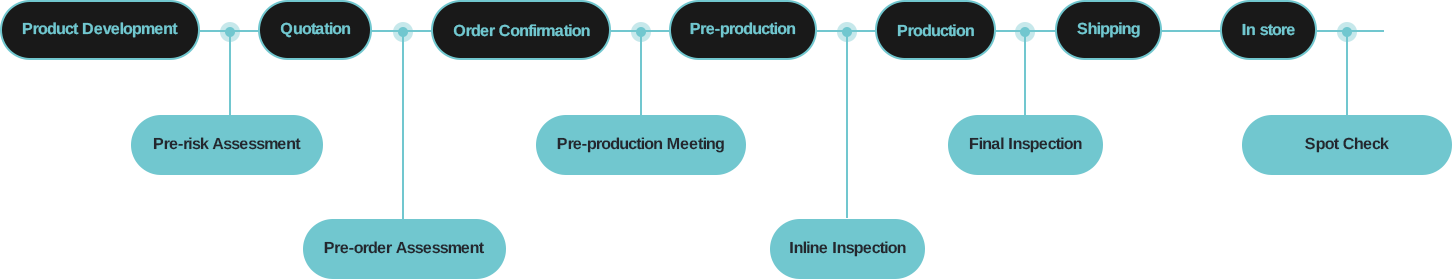

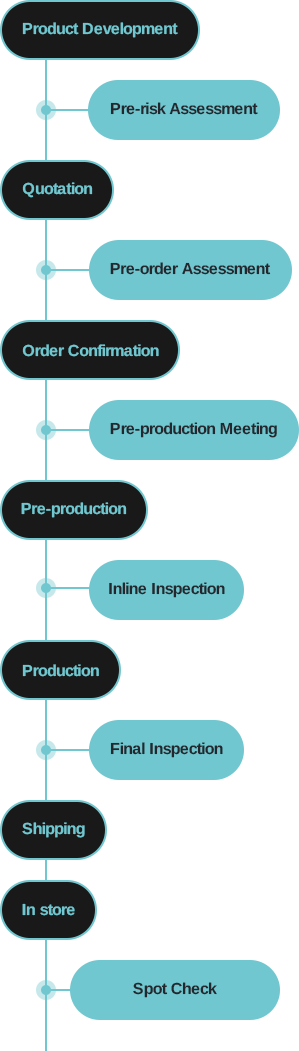

Stringent Quality Control

Apart from factory inspection, Coinus implements a quality management system that applies to all business processes. We have a professional quality management team who can implement, supervise, and follow up on all processes. The quality control team can reduce the risk of missteps to ensure continuous and stable product quality on all orders.

We perform an early risk assessment during the product development stage to guarantee optimal results during production. The inspection includes raw materials, product structure, size, and function.

Before we finalize the client’s order plan, production processes are confirmed by our competent team of inspectors.

We perform an early risk assessment during the product development satage to guarantee optimal results during production. The inspection includes raw materials, product structure, size, and function.

Quality control inspectors from Coinus visit the factory during the mass production and conduct quality assurance tests to ensure product consistency.

After mass production finished,Coinus inspectors will carry out on-site inspection to check everything,the quality,quantity,labelling,package,etc

Local merchandising unit visits the physical stores upon shipment arrival, checking the products and packaging. They will also do regular inspections to see points of improvement.

We perform an early risk assessment during the product development stage to guarantee optimal results during production. The inspection includes raw materials, product structure, size, and function.

Before we finalize the client’s order plan, production processes are confirmed by our competent team of inspectors.

We perform an early risk assessment during the product development satage to guarantee optimal results during production. The inspection includes raw materials, product structure, size, and function.

Quality control inspectors from Coinus visit the factory during the mass production and conduct quality assurance tests to ensure product consistency.

After mass production finished,Coinus inspectors will carry out on-site inspection to check everything,the quality,quantity,labelling,package,etc

Local merchandising unit visits the physical stores upon shipment arrival, checking the products and packaging. They will also do regular inspections to see points of improvement.

Factory Relationship Management

Management of factory relations is essential to Coinus since we regard the factories we work with as strategic partners. We can provide you with optimal prices, punctual delivery, and stable quality by working with our factory partners and utilizing sound management of production. Coinus can complete your performance goals and bolster your business through its optimized factory management.

Competitive Price

By actively seeking and negotiating deals with factories, we can provide market-oriented prices on our sporting goods.

Competitive Price

By actively seeking and negotiating deals with factories, we can provide market-oriented prices on our sporting goods.

On-Time Delivery

The optimum factory relationship management we foster ensures on-time delivery of your orders.

Sound Risk Management

Establishing a mutual relationship with key factories can reduce issues with availability, delays in supply, and low-quality products.

Sound Risk Management

Establishing a mutual relationship with key factories can reduce issues with availability, delays in supply, and low-quality products.

Performance Optimization

Strengthening our supply chain results in a streamlined purchasing process for optimized production.

Complete Certification

You can review the certification of the factories we work with, which will help you assess our capabilities in delivering quality sports goods.

adidas audit

BSCI audit

FIFA certificate